introducing

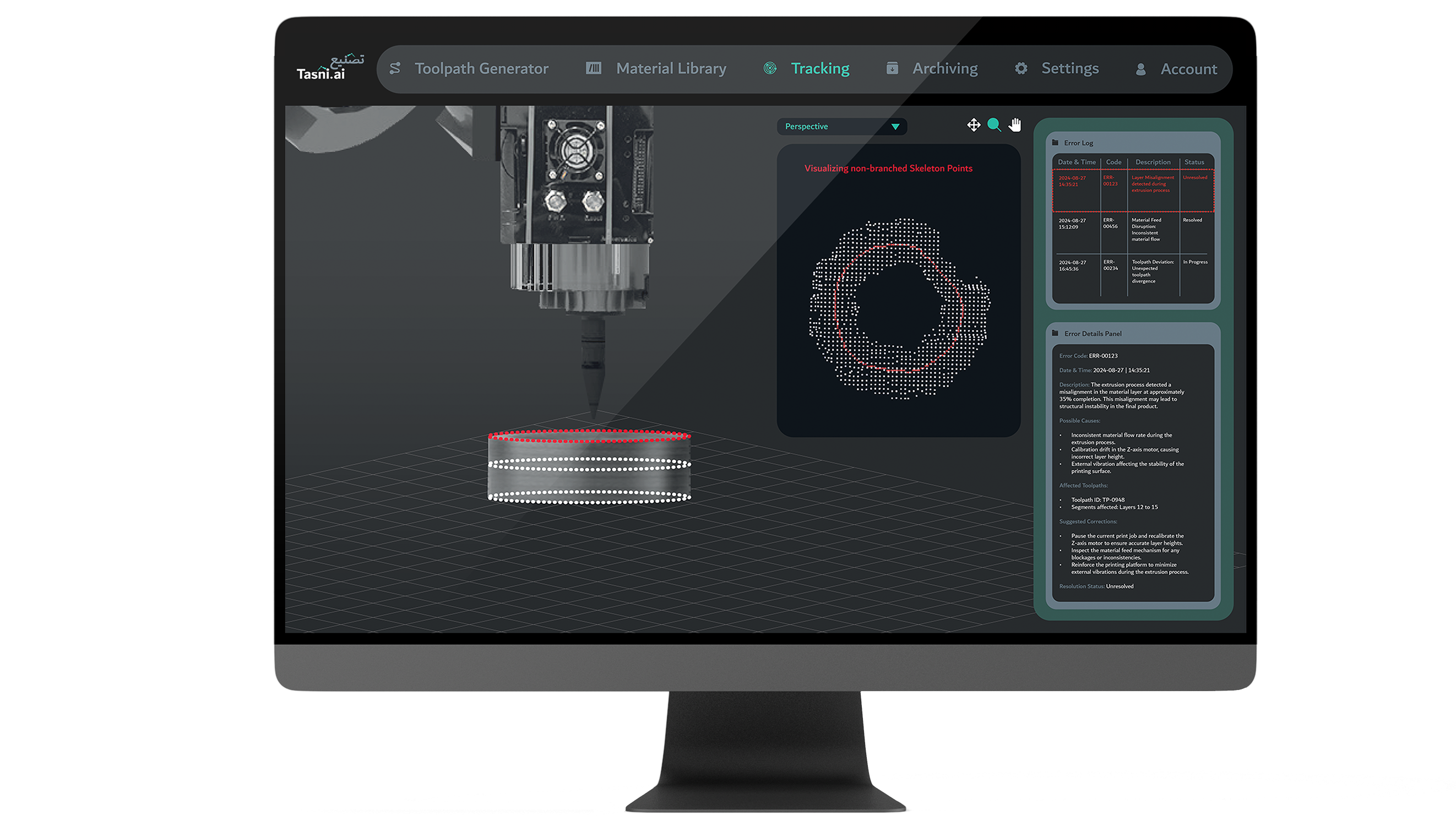

AI-Powered Manufacturing

A software solution enabling real-time optimization and error control for robotic fabrication

Real-time Error Detection and Correction

using custom AI algorithms and digital twin technology

AI-Driven Error Detection

Real-time monitoring and correction of errors using AI algorithms to improve accuracy in additive manufacturing.

Digital Twin Integration

The software employs digital twins to simulate and optimize manufacturing processes, ensuring alignment between virtual and physical outputs.

Material Behavior Mapping

Tracks and archives the behavior of materials during the printing process, allowing for precise adjustments and future optimizations.

Real-Time Feedback

Provides immediate feedback during production, enabling dynamic adjustments to toolpaths and extrusion settings.

Advanced Toolpath Visualization

Visual representation of the toolpath, offering users detailed insights into the progress and any deviations during manufacturing.

Bilingual Interface

Supports both English and Arabic, allowing seamless usability for diverse user groups.

a UAE-born system

blending academic research and industrial expertise

© 2024 Tasni.ai